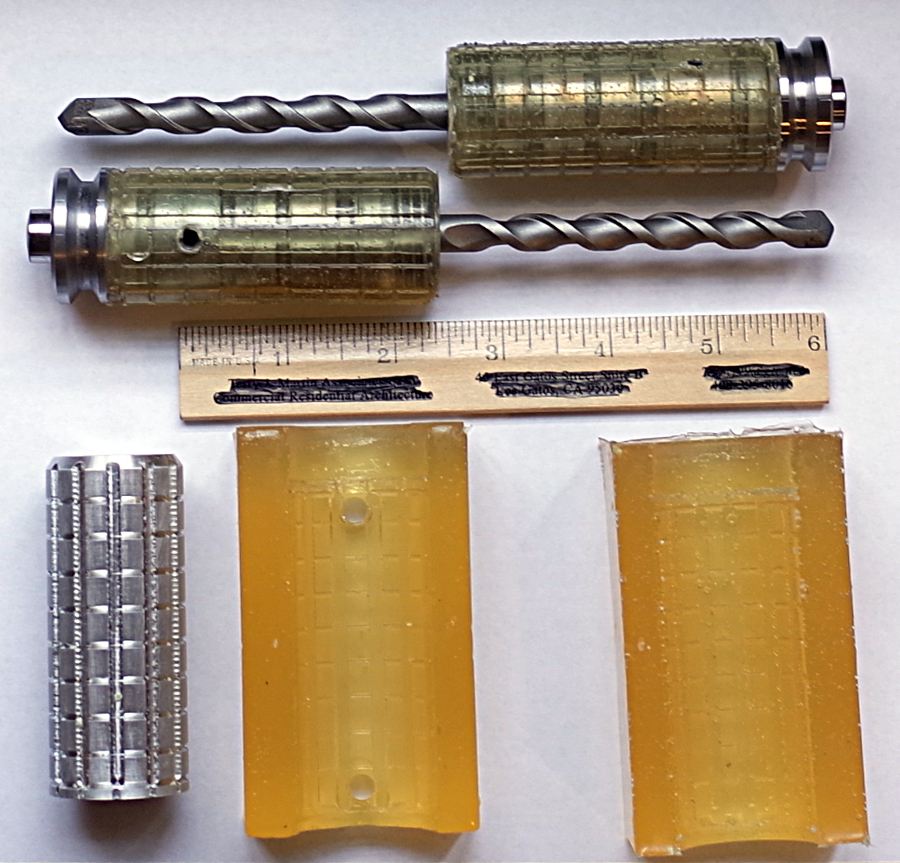

I made a couple urethane holders. Cosmetically they probably aren't so great but I think they are functionally good. The Shore A 70 urethane rubber feels better that I thought it would. It feels grippy enough. I made circumferential and longitudinal slots in the steel so the grip should not rotate or slide off. The rubber seems tough and tear resistant. Specs:

Mix Ratio: 2A : 1B by weight

Mixed Viscosity (cps): 3,000 (ASTM D-2393)

Specific Gravity (g/cc): 1.04 (ASTM D-1475)

Specific Volume (cu. in. /lb.): 26.5

Pot Life: 30 minutes (73°F/23°C) (ASTM D-2471)

Cure time: 16 hrs (73°F/23°C)

Color: Light Amber

Shore A Hardness: 70 (ASTM D-2240)

Tensile Strength (psi): 750 (ASTM D-412)

100% Modulus (psi): 250 (ASTM D-412)

Elongation @ Break: 750% (ASTM D-412)

Die C Tear Strength (pli): 200 (ASTM D-624)

Shrinkage: < .001 in./in. (ASTM D-2566)

In the photo you can see the two holders I've made, the aluminum form for the mold and the mold which I made from the same urethane material. The first holder has some clay (used to seal the mold) embedded in it and the bit end of the steel is slightly off center. For the second one I used some clear silicone grease to seal the mold so it doesn't have junk embedded in it and I fixed the mold setup so it stayed centered. I think the first one is as functional as the second but doesn't look quite as nice.

I could buy pigment and make the grip anything from black to fluorescent pink. They have some bubbles inside. There are also the positive and negative impressions of bubbles on the surface which only make them grippier.

If anybody is doing any drilling and would like the first one for prototype testing, it's yours so long as you use it and let me know the good and bad.