Another drilling experiment to report.

I have some 10mm x 110mm drill bits that I got from the UK a long time ago. When I first bought them, they seemed pretty good and then later the tips blew out in less than one hole so I gave up. After learning more about how sudden temperature changes destroy carbide, I realized that these bits started blowing out when I switched from hand sharpening them with a diamond file to using the green silicon carbide grinding wheel. So, I decided to try them again.

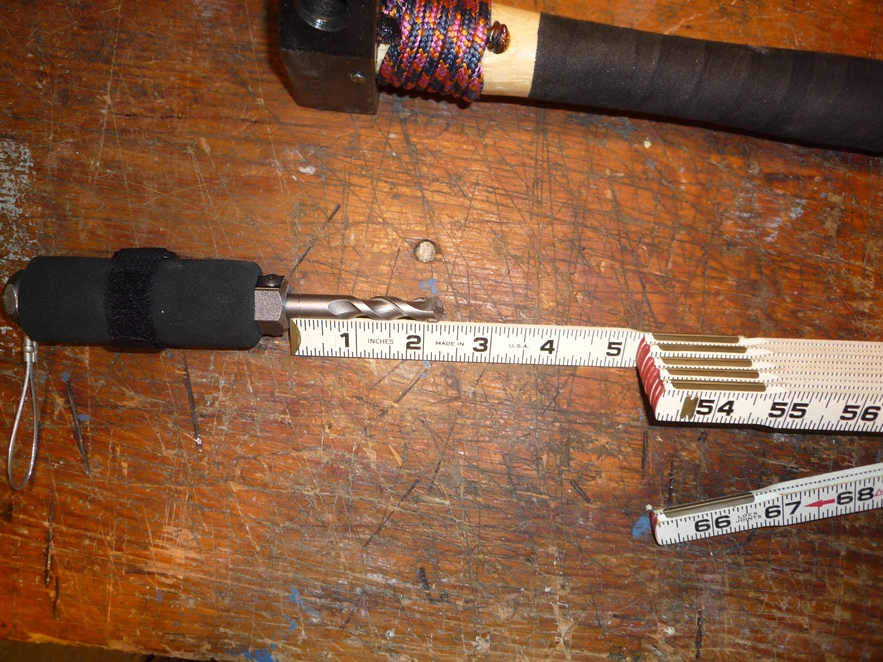

I believe that shorter bits will drill faster and that steps in the shank diameter will also slow down drilling. In hopes of making a fast drill, I put the bit in the lathe and tapered the little step in the shank. I sharpened the bit by hand and also reduced the width of the tip by hand to match a 3/8" bit.

I set to drilling and 7 minutes later, pouring sweat, I had a 2.1" deep hole. After the initial bum-out, I tried to figure out what went wrong and why it was so slow. I found that the angle between opposite faces of the tip is larger than the bit I used in the last test. So the 10mm bit was sharp but the tip angle wasn't as acute. I need to not only sharpen but change the angle of the tip. This will be hard work by hand and I wish I had a wet, diamond wheel but they are expensive.

Anyway, the bit held up fine for one hole anyway and I think the trouble I had was the heat generated in bench grinding and the fact that I kept quenching them while grinding trying to keep them cool.

If you want to try short 10mm bits I think these are OK. I got them from seller UKDrills on Ebay. Seems to be the same as this website:

www.ukdrills.com Item 48.100110 £10.46 for ten. Might be easier to contact them through Ebay. The only marking on the bit is a 10 in a circle so I don't know where they are made.

For sharpening I bought an EZE-LAP 36C 1 by 4 Coarse Diamond Pocket Stone with Sheath on Amazon for $15 which I like.

If anybody wants a DAMMERR T-shirt, contact me.

http://dammerr.com/